L2m Rail has developed an innovative Wheel Impact Load Detection (F-WILD) system in partnership with RDSO, Indian Railway, Government of India. Our F-WILD system captures the wheel signature as a train moves over the instrumented zone of the track and processes data in real-time. The processed information is stored in secured servers (private cloud) for all authorized persons to view through a customized GUI. Information on the critically damaged wheels is communicated through messages to designated authorities. Our solution enables the Railway companies to monitor the health of all rail wheels that pass over the ‘WILD-zone’ and assists in condition-based maintenance of rolling stock, thereby reducing the maintenance costs while improving the rolling stock life cycle.

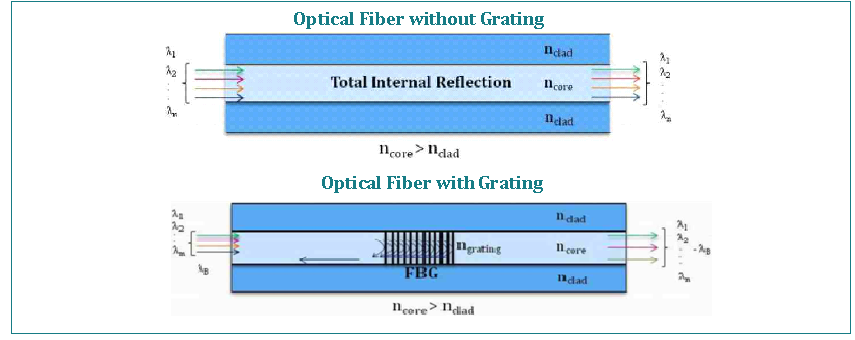

Fiber Bragg Grating Sensing Technology

Our next-generation F-WILD system incorporates revolutionary Fibre Bragg Grating (FBG) Sensors that offer both reliability and accuracy. FBGs are optical sensors which are highly stable and work well in harsh environment. They are immune to Electromagnetic Interference and do not require a power supply. They are small in size and easy to deploy on the tracks.

Our F-WILD system computes the dynamic and impact loads exerted by wheels on the rails. Optionally, lateral loads exerted by the wheels on the rails may also be provided. The results are presented to authorized users through a customized dashboard. All the data is stored on secured servers and the GUI is equipped with tools to generate various reports month-wise, year-wise, train wise, wheel wise and so on. Reports can be summarized based on wheel Load, Rolling Stock (Engine, Wagon and Tankers etc.) and Defective Rolling stocks.

Recent studies indicate that most equipment fails on a ‘random’ basis no matter how many assets are inspected. In other words, failures cannot necessarily be correlated to how maintenance was performed. Our sophisticated F-WILD system has evolved and improved the maintenance processes by replacing calendar-based periodic maintenance with predictive and prescriptive maintenance. Our F-WILD is an essential component of any performance-based rolling stock and asset management program, which monitors the wheel health of rail vehicles in real-time to ensure safe, efficient and productive train operations. L2M Rail’s F-WILD is cost-effective and reduces unplanned maintenance costs of rolling stock and tracks.